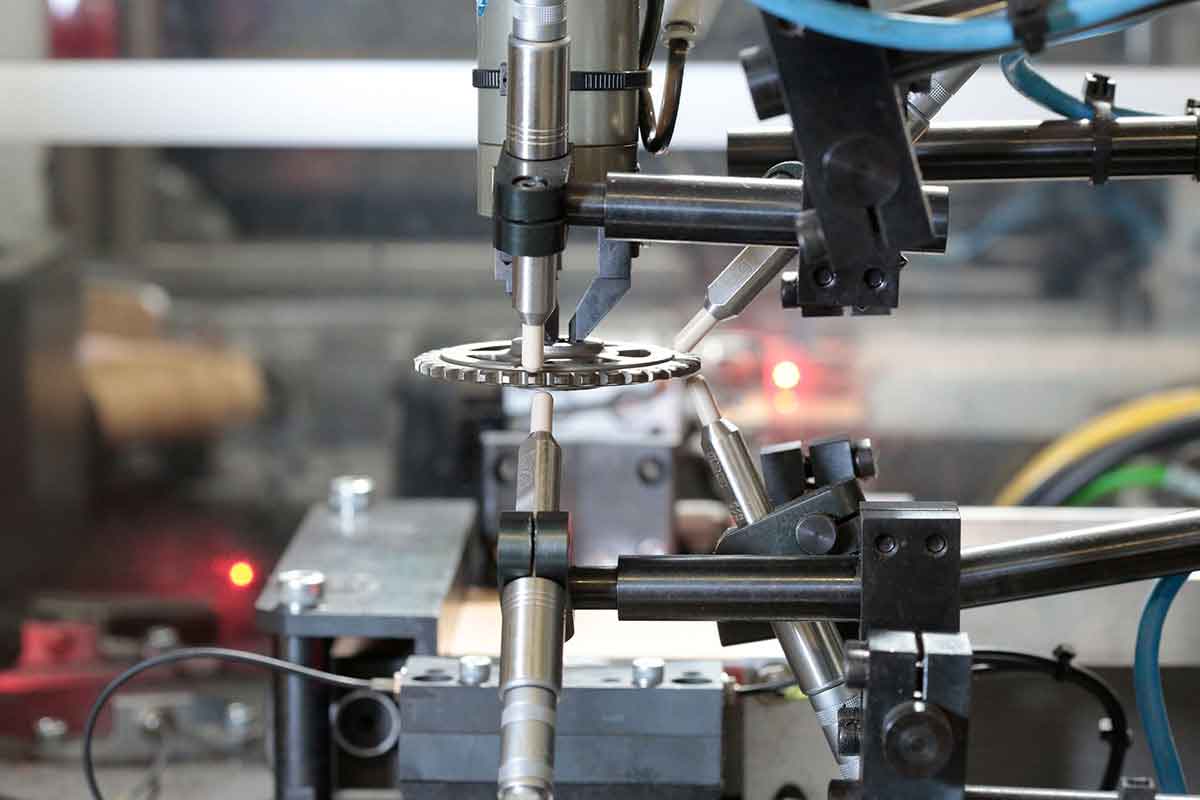

China Metal Powder is a full-service company offering complete design and engineering services, as well as process and product development from prototype through production. China Metal Powder is a pioneer in volume production of aluminum products. At China Metal Powder, we have more than a half a century of experience working with steel, iron, and stainless steel materials.

Without the dedication and focus of skilled employees throughout the organization, China Metal Powder would not be able to offer the outstanding customer support and problem-solving solutions that have been our hallmark since 1948. China Metal Powder’s goal is to design and produce the correct part for the customer using the most cost-effective process available, and to deliver the part to the customer on time while meeting specifications.

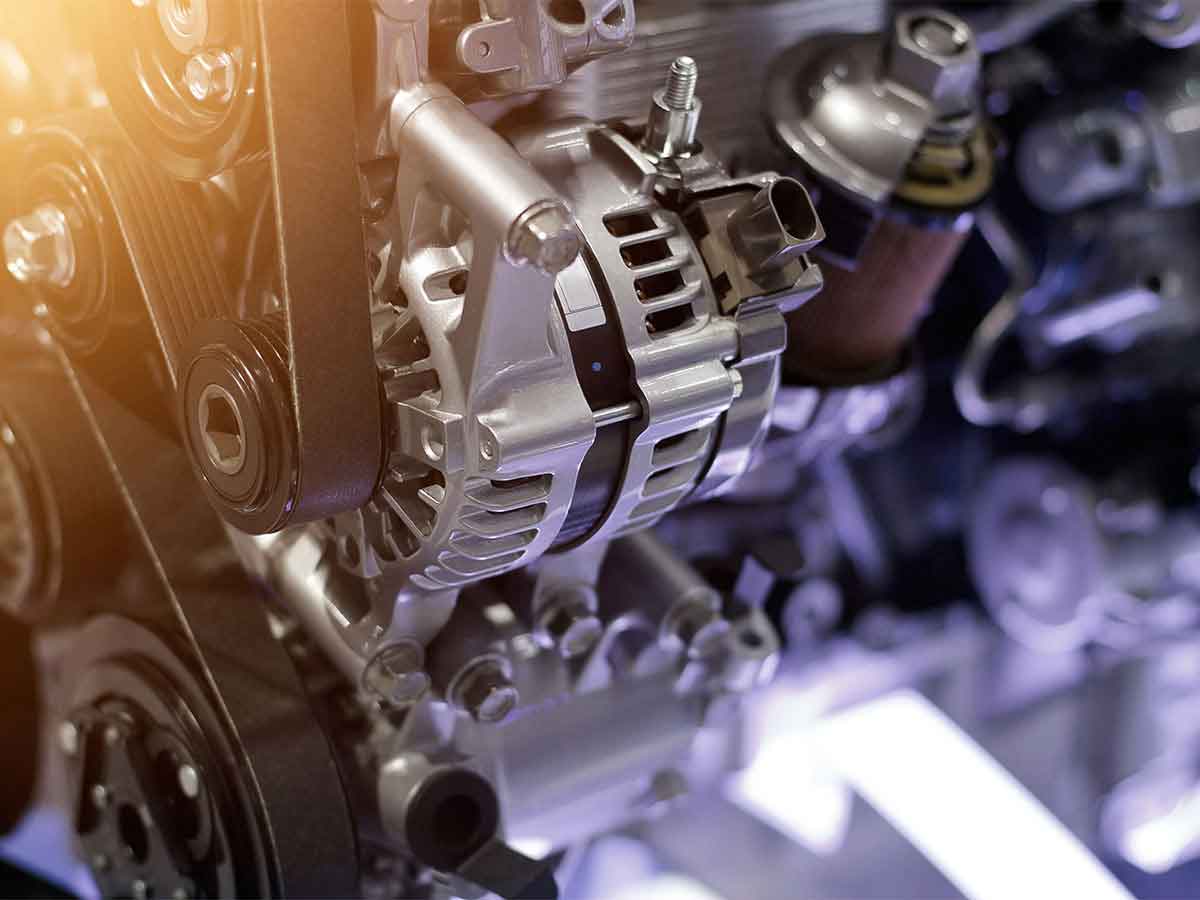

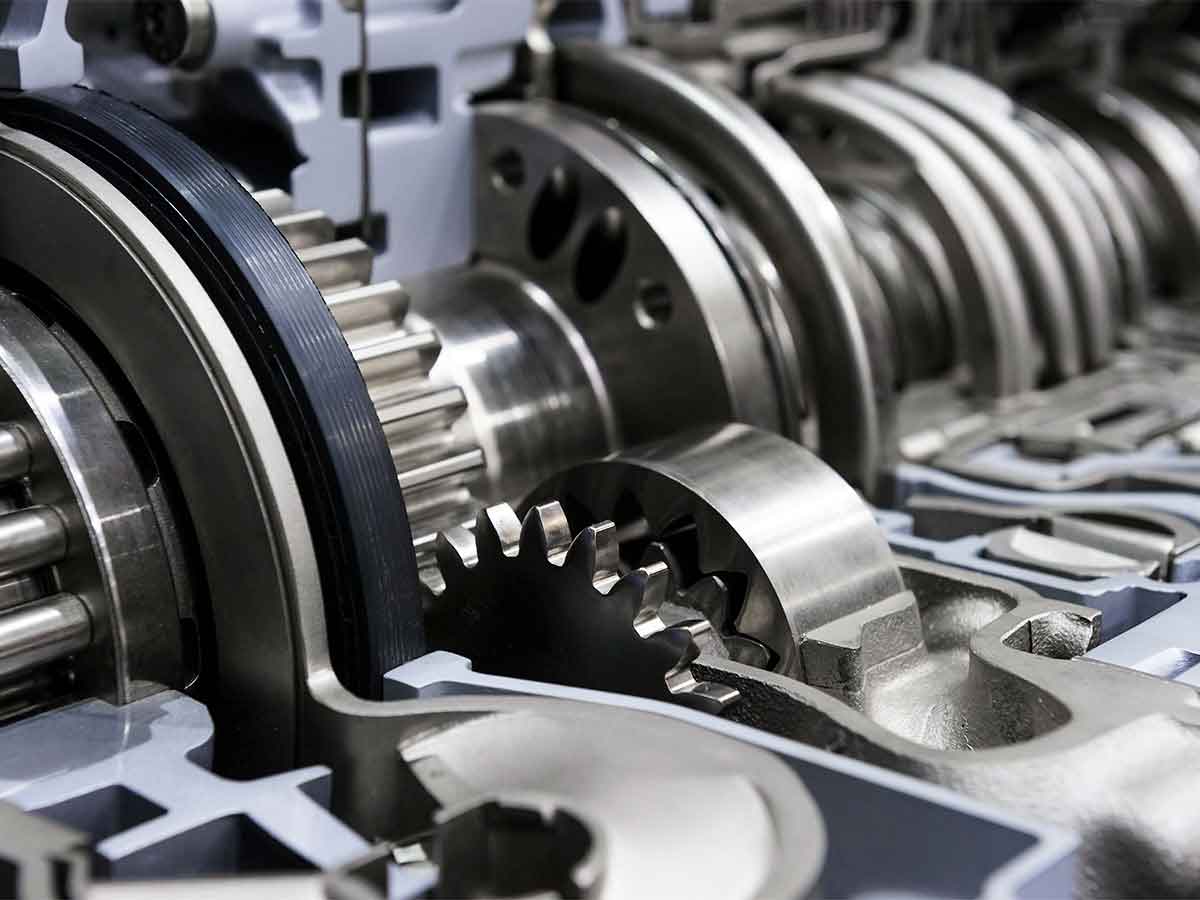

China Metal Powder is a major producer of components for engine and steering systems, and has won several awards of distinction for our products.

Our focused approach to the automotive market includes:

China Metal Powder has more than 40 years of knowledgeable and collaborative engagement in heavy truck and off-highway markets, including construction, mining, and agriculture equipment.

Our specialized expertise in fluid conveyance, along with a clear understanding of our customers’ product requirements, has enabled us to develop and produce solutions for the following applications:

China Metal Powder has more than 40 years of knowledgeable and collaborative engagement in heavy truck and off-highway markets, including construction, mining, and agriculture equipment.

Our specialized expertise in fluid conveyance, along with a clear understanding of our customers’ product requirements, has enabled us to develop and produce solutions for the following applications:

China Metal Powder has an extensive history in developing and producing innovative parts for fluid power and hydraulics applications. We specialize in critical system components by converting parts from forgings, castings, and machined parts to powdered metal. Our specialized knowledge covers the production of components as well as system optimization and collaborative design. Our material, tooling, and processing capabilities combined with design expertise make for a winning combination.

China Metal Powder is the world’s premiere producer of structural aluminum powder metal (PM) components. Our company leads the way in the use of pm aluminum for a variety of new and existing applications.

Aluminum’s light weight and strength provide an excellent strength-to-weight ratio. Aluminum offers product forms and alloys that surpass any other material. The design flexibility of aluminum is unparalleled, allowing designers to engineer optimum shape and performance for each specific application.

The processing of soft magnetic materials is another area of expertise for China Metal Powder. The most common soft magnetic pm materials used by China Metal Powder are pure Fe, Fe‑0.45% P, Fe-3% Si, and Fe-50% Ni. In addition, 410L and 434L plus similar grades of stainless are also good candidates for soft magnetic applications where corrosion resistance is needed. Soft magnetic pm materials are an important advantage for customers looking for improved performance of actuators, electric motors, and other electromechanical devices.

Higher temperatures during sintering and the use of pure hydrogen for oxide reduction improve soft magnetic performance. The absence of nitrogen eliminates the deleterious effects of the element, while the higher diffusion rates increase density, dissolve precipitates, and promote recrystallization and grain growth. In the case of silicon steel and phosphorus steel, the increased densification occurs with the aid of transient liquid phases.

China Metal Powder produces components from a wide variety of pm iron and steel alloys, which are generally known as ferrous pm alloys. These include admixed elemental ferrous alloys, diffusion alloyed steels, pre-alloyed low alloy steels, stainless steels, and tool steels.