China Metal Powder is an industry leader in the manufacturing technologies associated with the powder metallurgy process. China Metal Powder’s lean manufacturing operations include the extensive use of cell manufacturing and continuous flow manufacturing. Our overall goal of being best in class continues to drive our technical personnel to develop new manufacturing techniques, product applications, and materials.

Digital systems are a key component in all areas of China Metal Powder ranging from computer, numerically controlled manufacturing equipment to real-time production and quality control reporting, production control, and our customer interface. From our computer-controlled, multi-function presses and specially designed sintering furnaces to our secondary operations facilities and innovative processes such as powder metallurgy joining techniques, we have aggressively invested in equipment and programs to increase productivity, improve quality, and maximize employee safety.

China Metal Powder takes pride in implementing the latest engineering technologies and to deliver cutting-edge solutions for our customers. By understanding each customer’s unique application needs, we work with our partners to design parts that maximize results.

China Metal Powder developed a method to mold sprocket teeth in the center of the hub. The new method enabled design flexibility for tooth placement on the hub and eliminated a machining step after sintering.

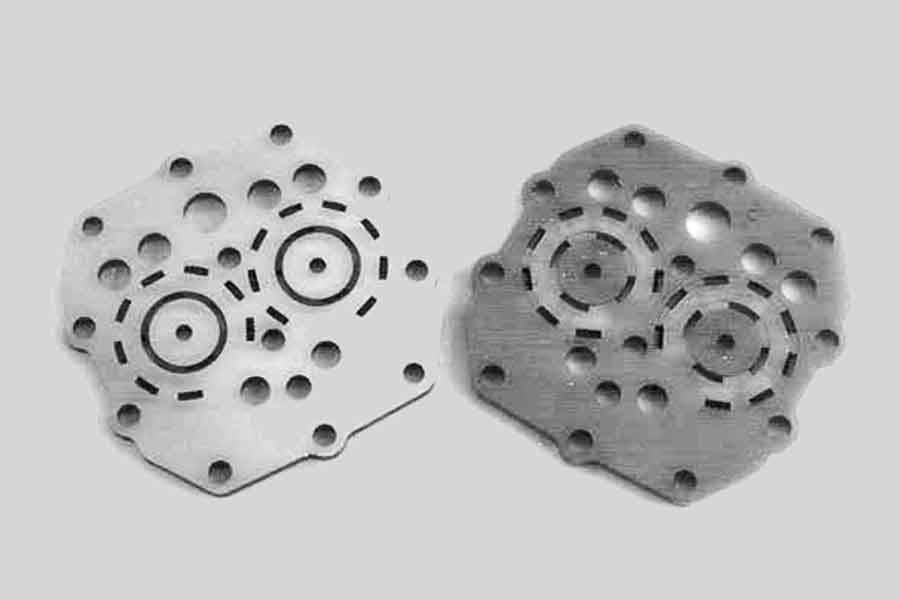

China Metal Powder developed a unique three-piece design for fluid power application. This innovative design utilized powder metal’s net shape capabilities as follows:

The original plate that was replaced by the powder metal component was a four-piece stamping, which was heavily machined, brazed, and ground.

China Metal Powder designed this cam assembly for small gas engines. The component is produced from two parts that are molded separately and then sinter-bonded in the sintering furnace. China Metal Powder’s design concept ability to produce the cam profile eliminated the requirements for significant machining of wrought materials.

China Metal Powder developed a stainless steel material for pump and appliance units that required corrosion resistance components from materials that were not available at the time of the design.

China Metal Powder developed a process for high-density, high-wear parts required for a critical driveline high torque component.

China Metal Powder developed an assembly of magnetic and non-magnetic components for a critical automotive powertrain application. The PM assembly replaced a stamping and forging process and improved the actuator performance for increased MPG.

China Metal Powder developed a unique aluminum powder with high strength and ductility equivalent to a sintered low carbon steel. An industrial application enabled a customer to replace a die cast hub with China Metal Powder’s PM aluminum hub, which not only improved strength but eliminated a significant amount of machining. Other applications include an automotive customer who was able to meet demanding new powertrain design requirements that were not possible with other technologies.

China Metal Powder developed a unique, high wear aluminum material to enable design of powertrain components for new automotive engine. This material outperformed die casting, which was unable to meet the stringent wear specifications required for the customer’s product.

China Metal Powder provided a near net shape aluminum PM component to replace a heavily machined wrought stainless steel ring. China Metal Powder’s upgraded product reduced weight and supplied a more economical finished product.

China Metal Powder’s engineering group provided the innovative design for this hand tool used for a plumbing application to remove and reinstall the trim on bathtubs. The tool reduces installation time by over 50%. Five of the six components in this assembly are powder metal. China Metal Powder also developed a proprietary material for wear and corrosion resistance.

China Metal Powder developed customized non-destructive testing systems for automated, high-volume production lines. Quality inspection improved and throughput increased.