Whether you seek to economically manufacture a high-quality computer component, a small medical instrument, or a firearm component, MIM is an ideal process.

At China Metal Powder, we translate complex designs with exacting specifications into reliable, cost-effective components. Our experienced development and metallurgical team convert the most difficult concepts into a reality not possible with other technologies.

China Metal Powder produces a variety of medical components through the MIM process, including endoscopic instruments, surgical instruments, and dental pliers. From design to production, we can assist in the complete manufacturing process and deliver value by creating near net shape components requiring little or no secondary operations.

China Metal Powder works with several medical applications, such as:

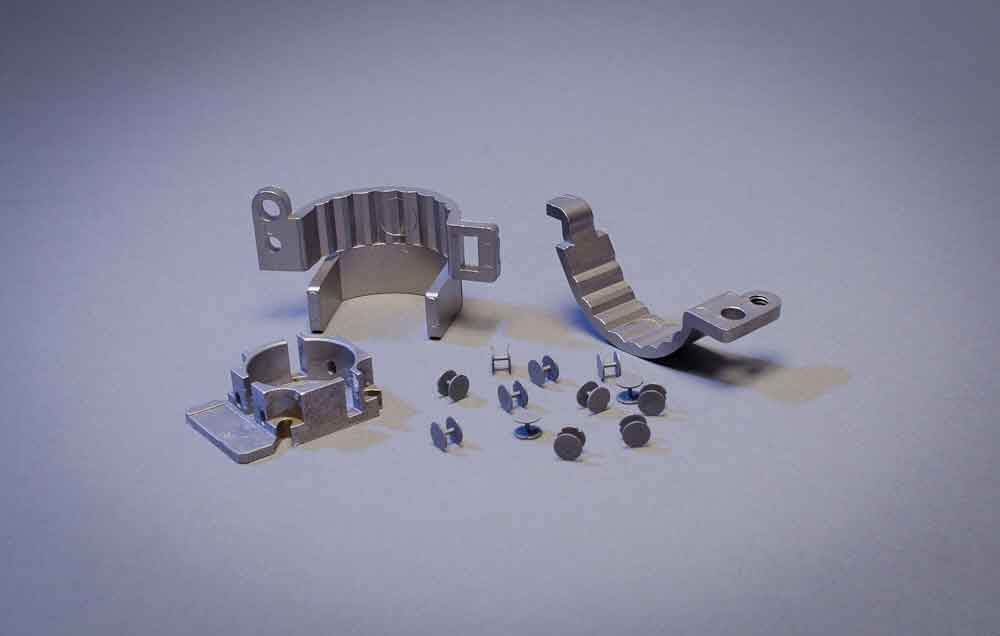

MIM is a cost-effective process for producing economical, high-quality firearms components. The process produces near net shape components eliminating costly machining or the inconsistencies of investment castings. China Metal Powder has extensive experience in producing turnkey firearm parts.

Benefits of working with China Metal Powder to manufacture firearms components through the MIM process include:

The aerospace and defense industries are rapidly converting from traditional metal forming techniques to take advantage the MIM process. MIM is an excellent way to manufacture aerospace components that are high-quality, accurate, cost-effective, and long-lasting.

Common materials used include:

One of the most common uses of MIM is for the creation of orthodontic devices, including brackets and hooks. While orthodontic devices were traditionally created using investment casting, manufacturers have realized the cost savings and high-quality products that MIM provides. MIM is able to produce strong, smooth, and precise components in a variety of metals, including stainless steel.

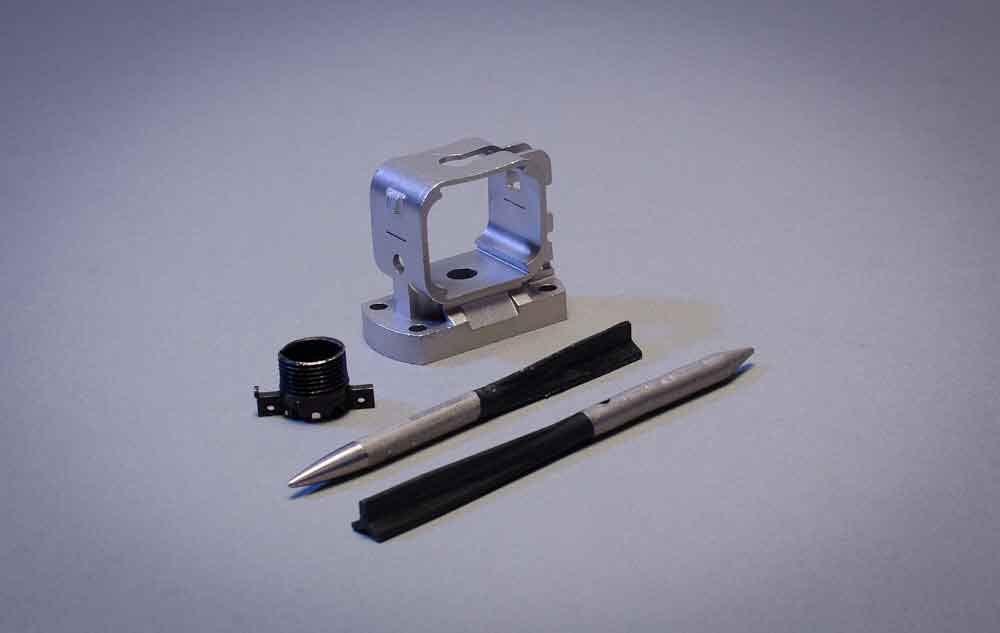

China Metal Powder has invested in the latest technology to keep pace with the fast moving telecom and electronics market. Our MIM process can produce components that are nearly net shape requiring little secondary operations and eliminating costly machining processes. The MIM process provides increased value.

China Metal Powder specializes in the design and manufacture of numerous electronics and electrical parts including:

China Metal Powder specializes in MIM of soft magnetic alloys, stainless steel, and an array of other metals. The MIM technique is ideal for producing small, complex electronics and electrical components with excellent mechanical properties.

MIM is capable of creating small, complex parts for use in a variety of industrial and consumer applications. Because MIM allows for high production volumes, the reduction or elimination of secondary machining, and a cost-effective price point, the technology is providing significant value for our customers.

China Metal Powder designs and manufactures components for the following applications: